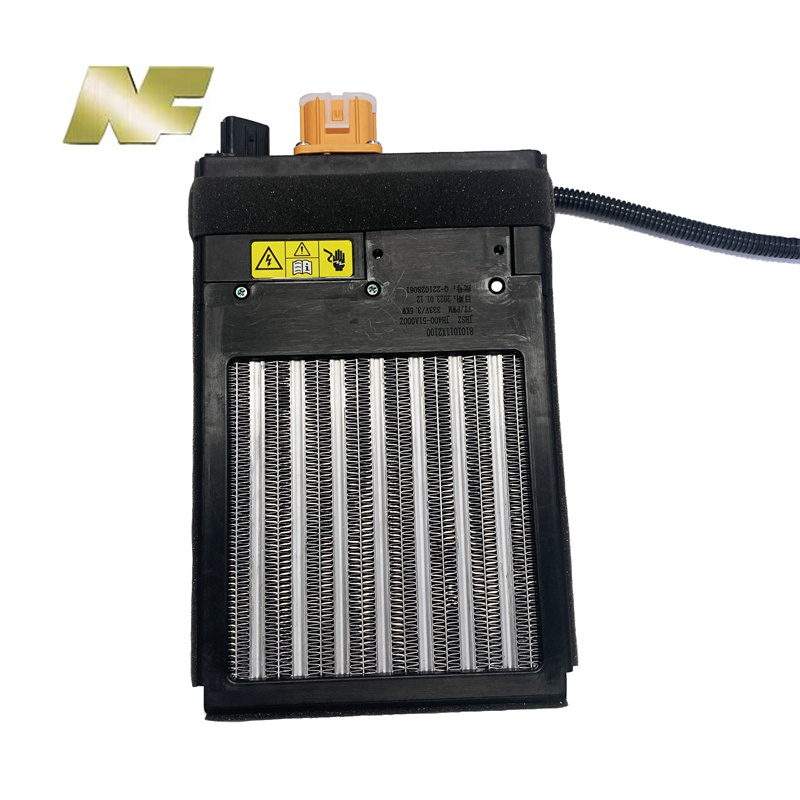

PTC Air Heater For Electric Bus

Description

Introducing our innovative PTC air heaters and EV air heaters, designed to provide efficient and reliable heating solutions for a variety of applications. Whether you need to heat the interior of an electric vehicle or provide warmth in a residential or commercial environment, our air heaters are the perfect choice.

PTC air heaters use advanced PTC (Positive Temperature Coefficient) heating technology to provide consistent, even heating. This technology ensures fast heating and precise temperature control, making it ideal for a variety of heating applications. With its compact design and energy-saving performance, PTC air heaters are a versatile solution for heating enclosed spaces.

Our EV air heaters are specifically designed to meet the heating needs of electric vehicles. As the demand for electric vehicles continues to increase, it is crucial to have a reliable heating system to provide comfort and warmth to passengers. Our EV air heaters are engineered to provide powerful and efficient heating while maintaining the energy efficiency required for electric vehicles. It is a compact, lightweight solution that can be seamlessly integrated into a vehicle's heating system.

PTC air heaters and EV air heaters are manufactured to the highest quality standards, ensuring durability and long-term performance. They are easy to install and operate and suitable for a variety of heating applications. Whether you need to heat a small room, car or any other enclosed space, our air heaters meet your heating requirements precisely and reliably.

In addition to excellent performance, our air heaters are designed with safety in mind. They have advanced safety features to prevent overheating and ensure safe operation at all times. This gives you peace of mind that our air heaters are not only efficient, but also safe to use.

With advanced heating technology, energy efficiency and reliable performance, our PTC air heaters and EV air heaters are the perfect heating solution for a variety of applications. Experience the comfort and reliability of our air heaters, making them an essential part of your heating system.

Technical Parameter

| Rated Voltage | 333V |

| Power | 3.5KW |

| Wind speed | Through 4.5m/s |

| Voltage resistance | 1500V/1min/5mA |

| Insulation resistance | ≥50MΩ |

| Communication methods | CAN |

Product Size

Application

FAQ

1. What is a high voltage PTC air heater?

High-voltage PTC (positive temperature coefficient) air heater is an electric heating device that uses PTC ceramic elements to generate heat. These heaters are commonly used in a variety of applications that require efficient heating of air, such as industrial processes, automotive systems, and HVAC systems.

2. How does the high voltage PTC air heater work?

The working principle of the high-voltage PTC air heater is PTC ceramics, and its resistance increases sharply as the temperature rises. When current passes through the PTC ceramic element, it generates heat due to its self-regulating properties. The heater maintains a constant temperature up to specific design limits without the need for additional control circuitry.

3. What are the advantages of using a high-voltage PTC air heater?

High-pressure PTC air heaters have the advantages of fast heating, self-regulation, energy saving, and safety. They heat up quickly, reaching the desired temperature in seconds. A self-regulating feature prevents overheating, making these heaters safe to use. Additionally, they require less energy to operate than other heating methods.

4. Can high voltage PTC air heaters be used in hazardous environments?

Yes, High Pressure PTC Air Heaters are available for use in hazardous environments. Designed to safety standards, these heaters can withstand extreme conditions such as high temperature, vibration and corrosive atmospheres. They are typically used in applications requiring explosion proof or ATEX certified heating solutions.

5. Are high voltage PTC air heaters suitable for outdoor applications?

Yes, High Voltage PTC Air Heaters are suitable for outdoor applications. They are typically used in outdoor cabinets, cabinets or equipment that may be exposed to low temperatures, humidity or freezing conditions. These heaters prevent damage from condensation and keep electronic components functioning properly in outdoor environments.

6. Can the high voltage PTC air heater be used as the main heating source?

High pressure PTC air heaters are primarily designed to be used as auxiliary heaters, not as primary heating sources. They are often used to supplement existing heating systems or to provide targeted heating in specific areas. However, for smaller spaces or well-insulated environments, they can be used as the sole heat source.

7. Does the high voltage PTC air heater need regular maintenance?

High pressure PTC air heaters do not require regular maintenance. The self-regulating feature of PTC ceramics prevents overheating, eliminating the need for complex control systems. However, it is advisable to check the heating elements for dust or debris build-up and to clean them regularly to ensure optimum performance.

8. Can the high-voltage PTC air source water heater be controlled by a thermostat?

Yes, high pressure PTC air heaters can be thermostat controlled. They can be integrated with thermostats or temperature sensors to maintain a specific temperature range. Once the desired temperature is reached, the PTC air heater self-regulates and automatically reduces power consumption, providing energy-efficient heating.

9. Is it safe to touch the high-voltage PTC air heater during operation?

The high-voltage PTC air heater is safe to touch during operation. The surface temperature of the PTC ceramic element is low, allowing safe operation even when the heater is operating at high temperatures. This feature prevents accidental burns or injuries, making it safe to install in a variety of environments.

10. Can high voltage PTC air heaters be customized for specific applications?

Yes, high pressure PTC air heaters can be customized for specific applications. Manufacturers often offer options in different power ratings, shapes, sizes and mounting methods to meet specific requirements. Additionally, they can be engineered to meet specific electrical and thermal specifications, ensuring optimum performance in a variety of applications.

4-300x300.jpg)